Part 1 is here.

Part 2 is here.

Part 3 is here.

Part 3b is here.

Part 4 is here.

For this post we’ll be focusing on the Volumetric Efficiency (%) of an engine. Last post we “guessed” at the volumetric efficiency of our engine to find our Airflow Rate (cfm). This time we’ll be kind of going backwards, using a logged Airflow Rate from an actual engine to calculate an engine’s real Volumetric Efficiency.

As we said before, the Volumetric Efficiency is a measurement of the ACTUAL Airflow Rate (the amount of air going through our engine) in relation to the Theoretical Airflow Rate under perfect circumstances and perfect engine performance. Since that isn’t possible, this measurement shows how “efficient” our engine is, and is thus in a percentage. For naturally aspirated engines, most are below 100%, since most circumstances aren’t perfect. But for forced induction engines, the Volumetric Efficiency can rise over 100% as we’re stuffing in a lot more air into the engine than the displacement is made for.

There are five steps to finding our actual Volumetric Efficiency. The first would be to log and record our engine’s data (this is the part that differs from the rest of the project, as we usually use manufacturer’s data and theoretical inputs). The second is to find the Air Density (lb/ft3) right then and there (time/location). The third would be to use that to find our car’s Actual Airflow Rate (cfm). The next is finding our Theoretical Airflow Rate (cfm), and then finally we use both those numbers to find our real Volumetric Efficiency. Let’s get started.

So first up is recording the data from our car. We’ll need three specific parameters:

- Engine speed (rpm)

- Mass flow rate (lb/min)

- Intake air temperature (oF preferrably)

After you’ve recorded each parameter, we can move on to the next step. The second step is to find the density of the air which was used by the engine. The problem is that the temperature we use is at the intake housing. By the time the air has arrived inside the engine, and is burned, the temperature has surely gone up, but this is the only accurate reading we can get before the air enters the cylinders. This is why we recorded the air temperature; since density is inversely related to the temperature of air. The only thing we need to do before that is to convert our air temperature into absolute temperature, or oR (degrees Rankine). To convert from Fahrenheit to Rankine we simply just add 459.67 to our Fahrenheit reading:

oR =

Easy. Just add your logged temperature (in Fahrenheit) to 459.67.

Here’s the real equation after you’ve done that, which finds the Air Density:

t1 is the temperature of air for a known density (we used 32oF)

ρ1 is the density of air for a known temperature (0.0808 lb/ft3)

t2 is our converted temperature reading (oR)

ρ2 is what we’re solving for (Air Density (lb/ft3)).

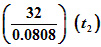

Which we can then change around our equation to solve for our Air Density (ρ2), which gives us (after we plug in our reference numbers for t1and t2):

Air Density (lb/ft3) =

We just solved for our Air Density, leaving just the logged temperature (converted to Rankine) to be plugged in. For our known/controlled ratio we used 32 degrees Fahrenheit and 0.0808 pounds per foot cubed. Just multiply the ratio by the converted logged temperature, and you’re done.

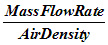

Ok, for step 3, we can solve for our Actual Airflow Rate. We need our Mass Flow Rate (lb/min) and the Density of the Intake Air (lb/ft3). Here’s the equation:

Actual Airflow Rate (ft3/min) =

Just divide your Mass Flow Rate by your logged Density.

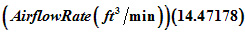

* And if you’d like to convert your Airflow Rate from ft3/min to cfm, the equation is here:

Airflow Rate (cfm) =

Note that this is the Airflow Rate we can use for our next step in determining a suitable compressor. This is obviously the more accurate reading, but it requires the time and effort (plus money) to record an engine’s exact data.

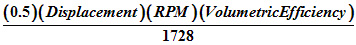

Step 4 is actually the equation from our last post which figured out our Theoretical Airflow Rate, but using 100% as our Volumetric Efficiency instead since this under perfect conditions. Just make sure your Displacement is in cid units. So here it is again:

Theoretical Airflow Rate (ft3/min) =

From our previous post. We’re just multiplying our Displacement, RPM, Volumetric Efficiency by 0.5, and then dividing by 1728 to convert our Displacement (which is in cubic inches) into cubic feet (cfm).

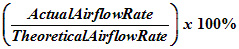

And our last step is calculating our actual Volumetric Efficiency. We just need our Actual Airflow Rate (cfm) and Theoretical Airflow Rate (cfm) which we just solved for. Here’s the equation:

Volumetric Efficiency (%) =

We’re dividng your Actual (real logged data) Airflow Rate by the Theoretical (under perfect conditions, using 100% Volumetric Efficiency) Airflow Rate, and then multiplying by 100% to get it in percent form.

This will give you your specific engine’s Volumetric Efficiency. This will be different for EVERY engine (even between two of the same engine models), as well as each time you log your parameters since air temperature and air density will change depending on both weather and location. But this is a good idea of how your engine is performing, whether it’s pre-tuning and modifying, or just comparing the health of your engine to others.

This is another way of finding your engine’s specifiic Airflow Rate instead of taking the manufacturer’s numbers . And instead of guessing our engine’s Volumetric Efficiency, we’re taking real world data and calculating our volumetric efficiency and our actual Airflow Rate, instead of using theoretical numbers based on manufacturer’s data.