Part 1 is here.

Part 2 is here.

Part 3 is here.

Part 3b is here.

There are two different ways we can go right now for our next step. This post focuses more on the theoretical and is thus not as accurate since we’re using manufacturer’s numbers and not real world numbers. The next post (Part 3b) will gather real world information for our specific engine so we can be more accurate. The “theoretical” way is more accessible as we can get the numbers we need from the internet, while the real world information gathering requires equipment and more time/money, but will obviously be more accurate. The parameters (variables) we’re solving/gathering are the same for both posts, we’re just going about it in different ways. Please read this section first before reading up on Part 3b.

So now that we’ve found our determined output and our required boost, it’s on to the next step: determining our exact turbo. We know that a turbo is comprised of basically two sections; the compressor and the turbine. The compressor is the “cold” side which compresses the air, and the turbine is the “hot” side which is powered by the exhaust gases. The first step in selecting the turbo is finding the right compressor.

To find the best compressor, we need to look at the airflow rate of our engine and the pressure ratio and compare that to each compressor to find the best match. Keep in mind where you want your turbo to be most effective, whether its in the low-rpm range, mid-rpm range, or only in the high-rpm range. Also remember that turbo is a match of both the turbine and the compressor, and both can be “mix and matched” to each application.

First up is finding our Pressure Ratio. The Pressure Ratio is the total absolute pressure produced by the turbo divided by the atmospheric pressure (14.7 psi). The total absolute pressure is basically the atmospheric pressure plus the amount of boost we’re running/going to run. If you don’t know the amount of the boost you’re going to run, just add 1 to the Performance Gain (%).

Pressure Ratio =

or

or

Add 14.7 to the amount of boost you’re going to run. Then just divide that by 14.7. Or if you’re using the second equation, just add one to your Performance Gain percentage (which should be converted to decimal form).

Next is the Airflow Rate. To find that, we’ll first need the following variables:

- Displacement (cid)

- Revolutions per Minute (rpm)

- Volumetric Efficiency (%)

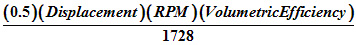

Once you’ve found your numbers, you can plug all that into this equation:

Airflow Rate (cfm) =

Lets break down the equation:

- The 0.5 is used as we’re calculating the airflow for a four stroke cycle engine, and its cylinders are filled every other stroke (twice for every four strokes).

- The Airflow Rate we’ll be calculating will be using the unit cfm, or cubic-feet-per-minute. This isn’t technically correct, as pounds-of-air-per-minute is the correct term, but cfm is more widely used. So, our airflow rate will be in cfm using feet. That’s basically how much air is moving through the engine at any given moment when we’re running the engine at that rpm.

- Our Displacement is the size of the engine. Since we usually measure our displacements using liters, we can convert liters to cid using this equation: cid = liter(s) x 61.02

- The Revolutions per Minute (or the Engine Load) is your engine’s RPM. We’re going to use your engine’s Maximum RPM for now, ie. where the rev limiter kicks in to get our engine’s maximum Airflow Rate.

- The Volumetric Efficiency displays how efficient our engine is at “using” the amount of air molecules vs the amount of air molecules in the air. The Volumetric Efficiency is different for every engine, and there are ways to calculate it, but most engines are averaged around 80-90% Ev. I’ll post the equations to accurately find your Volumetric Efficiency in the next post.

All that is multiplied together and then divided by 1728 to convert our Displacement (which is in cubic inches) into cubic feet (cfm) and that’s your Airflow Rate for your engine (in cfm) at your specified rpm.

Note that for this equation, if we’re calculating for an engine of the same dimensions, the resulting Airflow Rate would be linearly proportional to the Engine Load (or Revolutions per Minute). This proves that lowering Engine Speeds results in a lower Airflow Rate.

So after you’ve found your Airflow Rate for your normally aspirated engine (pre-turbo), we need to calculate what the Airflow rate will be with our turbo installed. Remember your Pressure Ratio from before? Well all we do is multiply our pre-turbo Airflow Rate (cfm) with our Pressure Ratio and we get our new Turbo Airflow Rate. Here’s the equation:

Turbo Airflow Rate (cfm) = ![]()

Just multiply the Airflow Rate by the Pressure Ratio.

This sums up finding the Airflow Rate, for both our stock engine, and our desired turbocharged engine. The next post will be focusing on the Volumetric Efficiency, as I’ve decided to post that separately as to not confuse people. After that, I’ll continue by using our Airflow Rate numbers and Pressure Ratio numbers to find a suitable compressor.

I don’t know If I said it already but …Cool site, love the info. I do a lot of research online on a daily basis and for the most part, people lack substance but, I just wanted to make a quick comment to say I’m glad I found your blog. Thanks, 🙂

A definite great read..Jim Bean

Thanks! Glad you enjoyed it.

Super-Duper site! I am loving it!! Will come back again – taking your feeds too now, Thanks. 🙂

amazing stuff thanx 🙂